In the rapidly evolving landscape of material handling and industrial logistics, the selection of the right machinery is paramount. Among the most versatile and essential components found in modern warehouses and manufacturing plants is ball roller equipment. From simple gravity-fed conveyor systems to complex automated sorting lines, ball roller equipment serves as the backbone of fluid movement.

This comprehensive guide explores the intricacies, applications, and benefits of integrating high-quality ball roller equipment into your workflow.

Understanding the Fundamentals of Ball Roller Equipment

At its core, ball roller equipment consists of a housing unit that holds a large, omnidirectional load-bearing spherical ball. This ball rests on many smaller balls, which allows the main ball to rotate freely in any direction. This unique design distinguishes ball roller equipment from traditional cylindrical rollers, which are restricted to linear movement.

How Ball Roller Equipment Works

The mechanical advantage of ball roller equipment lies in its ability to reduce friction while allowing 360-degree movement. When a heavy object is placed on a bed of ball roller equipment, the load is distributed across multiple points of contact. Because the balls can rotate in any direction, the operator can push, pull, or rotate the load with minimal effort. This makes ball roller equipment an indispensable tool for ergonomics and precision.

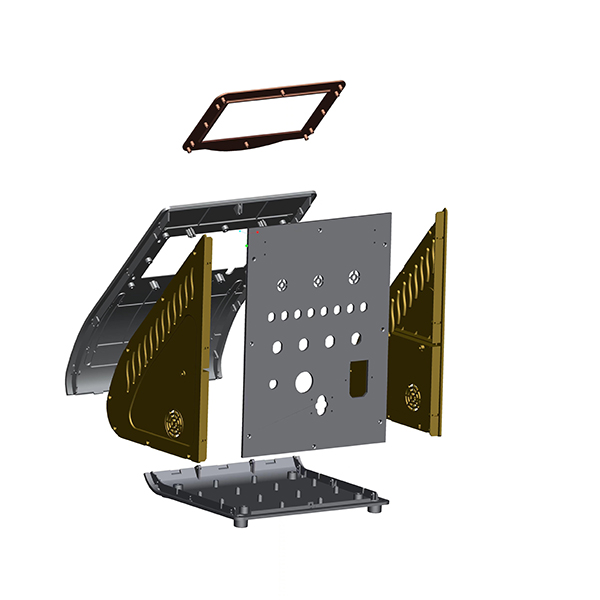

Key Components of Ball Roller Equipment

To appreciate the durability of ball roller equipment, one must look at its construction. Typically, ball roller equipment is made from:

-

Carbon Steel: Ideal for standard industrial environments.

-

Stainless Steel: Best for food processing or corrosive environments.

-

Nylon/Plastic: Used for fragile materials that require a “soft touch” to prevent scratching.

The Diverse Applications of Ball Roller Equipment

The versatility of ball roller equipment means it is found in sectors ranging from aerospace to e-commerce. Anywhere a heavy load needs to change direction quickly, you will find ball roller equipment.

Ball Roller Equipment in Airport Cargo Handling

If you have ever looked at the floor of a cargo plane or a luggage sorting area, you have seen massive installations of ball roller equipment. Airports rely on ball roller equipment to move heavy shipping containers (ULDs) into precise positions for locking. The omnidirectional nature of ball roller equipment allows ground crews to spin 5,000-pound crates with just a nudge.

Ball Roller Equipment in Manufacturing and Assembly Lines

In assembly plants, workers often need to rotate a product to install components on different sides. A workstation equipped with ball roller equipment allows for “spin-in-place” functionality. By using ball roller equipment, manufacturers reduce the risk of workplace injuries caused by heavy lifting and awkward twisting.

Ball Roller Equipment in Packaging and Distribution

Distribution centers are the heart of the modern economy. Ball roller equipment is frequently used at “transfer stations”—the points where one conveyor belt meets another at a right angle. Without ball roller equipment, packages would get stuck or require complex mechanical pushers. Ball roller equipment provides a seamless transition for boxes of all sizes.

Benefits of Investing in High-Quality Ball Roller Equipment

Choosing the right ball roller equipment is not just about moving boxes; it’s about optimizing your entire ROI.

Improved Ergonomics with Ball Roller Equipment

One of the primary reasons companies install ball roller equipment is to protect their human capital. Manually dragging heavy pallets causes strain. However, ball roller equipment converts sliding friction into rolling friction, which requires significantly less force. By implementing ball roller equipment, companies see a measurable drop in repetitive strain injuries.

Space Efficiency and Ball Roller Equipment

Traditional conveyor curves take up a lot of floor space. Ball roller equipment allows for “T-junctions” and “X-junctions” in a very small footprint. Because ball roller equipment allows for 90-degree turns without a radius, you can pack more processing power into a smaller warehouse by using ball roller equipment strategically.

Durability and Low Maintenance of Ball Roller Equipment

Industrial-grade ball roller equipment is designed to withstand harsh conditions. Many ball roller equipment units feature self-cleaning holes that allow debris to fall through rather than jamming the mechanism. When you invest in high-end ball roller equipment, you are investing in a component that can last for millions of rotations with minimal upkeep.

Selecting the Right Ball Roller Equipment for Your Needs

Not all ball roller equipment is created equal. To get the best results, you must match the ball roller equipment specifications to your specific load requirements.

Load Capacity of Ball Roller Equipment

Before purchasing ball roller equipment, you must calculate the weight of your heaviest item. It is a common mistake to divide the weight by the number of rollers. However, since surfaces are rarely perfectly flat, you should assume only three units of ball roller equipment are supporting the load at any given time. Always over-specify your ball roller equipment to ensure safety.

Environmental Factors for Ball Roller Equipment

If your facility is a “clean room” or a chemical processing plant, your ball roller equipment needs special coatings. For example, galvanized ball roller equipment resists rust, while specialized seals in ball roller equipment can prevent fine dust from entering the ball bearing chamber.

Installation and Maintenance of Ball Roller Equipment

To ensure the longevity of your ball roller equipment, proper installation is key.

Proper Spacing of Ball Roller Equipment

To ensure smooth movement, the “rule of thumb” for ball roller equipment is that the smallest item being moved should always be in contact with at least three balls. If the ball roller equipment is spaced too far apart, the item will “dip” between the rollers, causing a jam.

Cleaning and Lubricating Ball Roller Equipment

While many modern types of ball roller equipment are advertised as “lubricated for life,” periodic inspection is vital. Dust and grit are the enemies of ball roller equipment. A quick blast of compressed air can keep your ball roller equipment spinning freely for years.

Future Trends in Ball Roller Equipment Technology

As Industry 4.0 takes hold, even simple components like ball roller equipment are evolving.

Smart Ball Roller Equipment

We are beginning to see ball roller equipment integrated with sensors that can detect the weight and speed of the items passing over them. This “smart” ball roller equipment can feed data back to a central management system to identify bottlenecks in real-time.

High-Performance Materials in Ball Roller Equipment

New ceramic balls are being used in high-end ball roller equipment to provide even lower friction and higher heat resistance. These advancements ensure that ball roller equipment remains relevant even as conveyor speeds increase.

Conclusion: Why Ball Roller Equipment is Indispensable

In conclusion, ball roller equipment is more than just a set of metal spheres. It is a critical engineering solution that drives productivity, enhances safety, and saves space. Whether you are building a small DIY workshop or a massive international logistics hub, choosing the right ball roller equipment will define the efficiency of your operation.

The world moves on ball roller equipment. By understanding the different types of ball roller equipment, their maintenance needs, and their vast applications, you can ensure that your business stays in constant, fluid motion. Don’t overlook the power of the sphere—invest in quality ball roller equipment today.